[Article by Nane Zietsman]

The Fourth Industrial Revolution has been a widespread topic amongst all stakeholders of the global polity, from the private and public sectors to civil society and academia. As with any rising phenomena, new data are presented on a daily basis with many gaps still left to be filled. Dale Sparrow, Stellenbosch University Mechanical and Mechatronic Engineering Ph.D. student successfully identified such a gap and dedicated his studies to create an effective solution for the presented issue. “At the start of my Master’s degree, we focused on identifying the biggest shortcomings in existing research regarding the Fourth Industrial Revolution.” With the guidance and support of his supervisor, Dr Karel Kruger, they established that the integration of human workers is often mentioned as a side note in existing research on smart machinery- and factory control systems. This finding led them to further investigate the integration of human workers and these systems within the South African landscape.

According to Sparrow, South Africa has a majority of human workers in manufacturing. While human workers are often only considered for social-economic reasons, that is not the only factor at play. “Humans are unmatched in their intelligence, agility, and problem-solving ability.” Sparrow, therefore, believes that it is beneficial to include human workers in the decision-making circle of a digital manufacturing space so they may contribute these strengths.

He further explains that this inclusion does present difficulties when humans and other digital assets try to communicate due to a difference in language and the way in which these entities interpret and process information. They solved this issue by means of an administration shell – a digital personal assistant that communicates with the administration shells of other people and equipment on behalf of the human workers. “These administration shells are a timely solution that empowers workers to share information with machines, co-workers or supervisors without the burden of having to track them down, speak the machine’s language or memorize everything that needs to be communicated.” The administration shell is further capable of receiving information and instructions from machines and formulating it into a language that the human worker can clearly understand.

In order to design an architecture by which the administration shell could be developed, the design had to be generalized for a wide variety of applications. This resulted in the Biography-Attributes-Schedule-Execution (BASE) architecture, named to highlight the four core components of the architecture. The next step was to conduct a case study in a real manufacturing environment. This was achieved by equipping workers at Advanced Aerospace Technologies (AAT) with BASE administration shells. These workers were able to communicate their work progress or problems directly to the administration shell of their supervisor by means of a tablet resulting in the supervisor gaining access to real-time production information. This enabled the supervisor to make quick and informed decisions.

Owing to the noticeable value the implementation of Sparrow’s BASE administration shell added to the company’s production and processes, AAT requested that the system be implemented on a more permanent basis. Following ATT’s interest in the BASE administration shell Sparrow founded the spin-out company, Cybarete. His endeavours were greatly supported by Dr Karel Kruger and Prof. Anton Basson, heads of the Mechatronics, Automation and Design (MAD) research group at the Department of Mechanical & Mechatronic Engineering. Sparrow is currently working with the MAD group to align and support the research of postgraduate students with Cybarete’s commercial implementation of the BASE architecture.

One cannot admire the BASE administration shell without admiring the individuals behind its creation. Sparrow crossed paths with Dr Kruger as an undergraduate student when he shared his experience of control systems with him. “Dale’s curiosity and passion for engineering were evident. I could see him as the type of engineer that spends his free time building airplanes and drones or programming games.” It was at the Jac van der Merwe Competition for Innovation where Dr Kruger and Sparrow finally combined their thoughts. “I was on the judging panel of the Jac van der Merwe Competition for Innovation where Dale was one of the contestants.

We started discussing the importance of people in the manufacturing environment and how they are often excluded and overlooked due to the weak integration in the digital manufacturing space. It was during this discussion that I could convince Dale to use his Master’s degree to investigate, and hopefully solve, this issue.” According to Dr Kruger, Sparrow went above and beyond to conduct research on the topic. “The end result was the design of an architecture and platform that represents, supports and fully utilises people in the cyberspace”. By the end of 2019 Sparrow’s Master’s degree was upgraded to a Ph.D. He successfully defended his Ph.D on the 3rd of February 2021 and will be graduating in March/April.

“Dale represents a special amalgamation of engineering ingenuity and creativity. He has an infectious passion for the BASE architecture and Cybarete and he is definitely the type of student that will carry our faculty’s name high in the engineering world.” – Dr Kruger

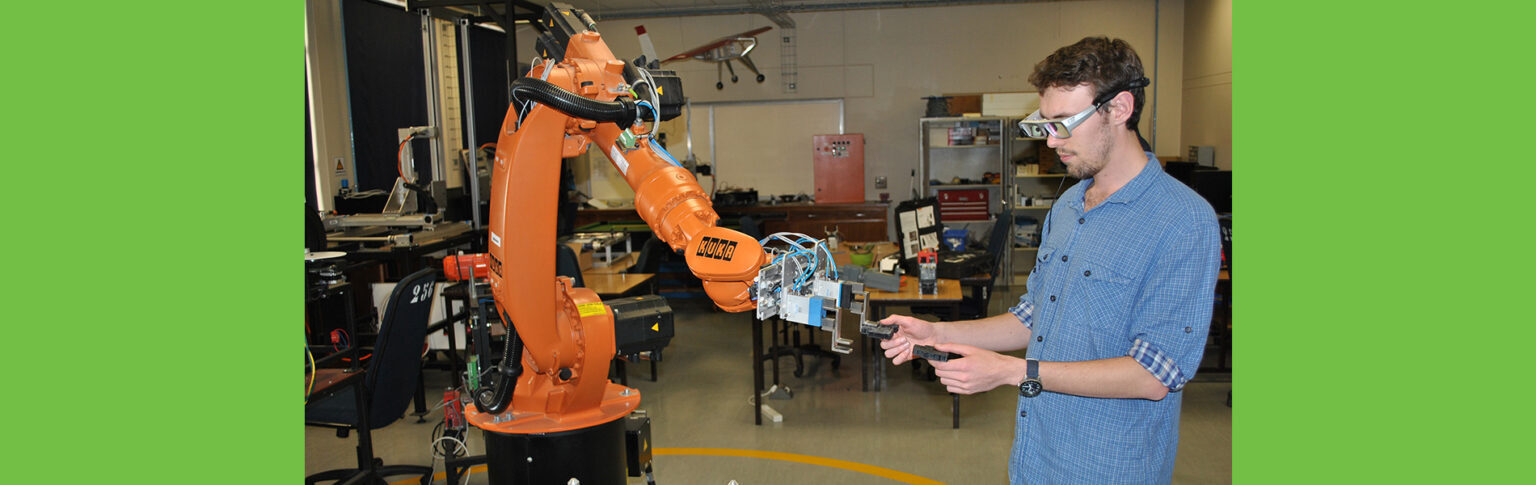

Photograph: Dale Sparrow’s research on human integration in Industry 4.0 in the Mechanical and Mechatronic Automation Lab.