Article by Prof Johan van der Spuy

In early April 2020, the South African Department of Trade, Industry and Competition mandated the South African Radio Astronomy Observatory (SARAO) to manage the local development of ventilators in support of the government’s response to combat the COVID-19 pandemic. The National Ventilator Project Manager, Willem Esterhuyse from SARAO, approached the Department of Mechanical and Mechatronic Engineering to assist with the testing of a concept Continuous Positive Airways Pressure (CPAP) device for this purpose. As the name implies, a CPAP device ensures a continuous supply of pressurised air to assist with the breathing process of a patient.

A very basic laboratory set-up was prepared with assistance from Dr Johan van der Merwe of the Biomedical Engineering research group in the Department and a number of personnel were asked to voluntarily provide assistance to the project on very short notice.

Since the country was still under stage 5 lockdown, special permission had to be obtained from the relevant authorities for persons to travel to and enter the University premises. Thanks to remote assistance from the administrative personnel in the Department, it was possible to source and purchase items like medical oxygen, oxygen sensors, tubing, flow sensors and regulators. A number of components had to be manufactured in the Mechanical and Mechatronic Engineering Workshop and Ferdi Zietsman from the workshop gave on-site assistance to the project while testing took place. Cobus Zietsman assisted with the sourcing of instrumentation from the Department’s instrumentation store.

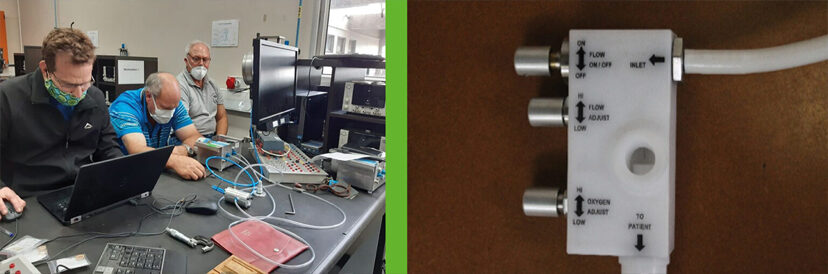

The specific CPAP device that was tested (photo right) was manufactured from a design that was published on-line by engineers from University College Londen (UCL) and Mercedes Formula One. The device works on the principle of air-entrainment. The pressurised oxygen supply is accelerated through a very small nozzle (the actual design specifies a hypodermic tube) that entrains atmospheric air into the gas stream before it is supplied to the patient. By regulating the oxygen supply, along with an adjustable Positive End Expiratory Pressure (PEEP) valve, the pressure, flow rate and oxygen content of the gas supply can be adjusted. The device can therefore be used to supply a pressurised oxygen-rich gas stream to a patient without the need for an additional compressed air supply. The tests showed that the device performed as expected.

Although the Department played a minor role in the overall NVP, the test results obtained from these experiments enabled the engineers from SARAO to form a clear and accurate picture of the capabilities of the specific CPAP device and to enable them to evaluate the results obtained from other devices developed by industry.

The devices that were tested, were manufactured in the workshops of the South African Astronomical Observatory (SAAO) under the guidance of Ockert Strydom. The costs for the assistance provided by the Department were carried by the Vice-Rector (Research)’s special COVID-19 fund. Mention should also be made of the Clinical Engineering Department at Tygerberg Hospital and Arrabon Medical Solutions who assisted with the supply and loan of equipment to the project on very short notice.

Photographs:

Left: Testing components for the CPAP device, from the left are Japie Ludick (SARAO), Ferdi Zietsman and Cobus Zietsman (both from the Department of Mechanical and Mechatronic Engineering).

Right: CPAP Device, as tested.