Initially, Oscar Röhrs was torn between pursuing a bachelor’s degree in Medicine & Health Sciences or Engineering. He opted for the latter. However, a few years later he was thrilled to include his interest in the medical field when choosing a topic for his master’s degree, titled Development of a canine knee implant. He received his master’s degree in Mechanical Engineering from Stellenbosch University in April 2020.

Oscar comes from a family of engineers and says: “I have a rich family history in Engineering, with about half of my extended family having pursued careers in the Engineering field, so in the end it seemed a natural fit for me. I initially chose mechanical engineering, because compared to the other engineering disciplines, this was where I felt most at home – where my academic interests felt most aligned. It is however a very broad field, and I didn’t know where I wanted to go exactly. I saw this as an opportunity to have more open doors, to have the freedom to decide which area of mechanical engineering I felt most drawn to by the end of my studies.”

His background and where he grew up, played a big role in forming his interests and influencing his eventual field of research. Oscar elaborates: “I am proudly South African, with German roots. I grew up on a farm near Piet Retief where I spent many hours with my siblings, parents and grandparents in and around the farm, helping out and having fun. Growing up with pets, farm animals and wildlife, I also garnered a genuine love and respect for all types of animals. I was blessed enough to be able to do and build random things to keep my young mind and body active. From building chairs, stilts and bicycle ramps, to climbing anything that could even be remotely perceived as climbable, which is where my love for rock climbing started. I was given the creative freedom not only to think of new things to keep myself entertained, but also to build the things I thought of.”

Oscar became aware of the field of Biomedical Engineering in his final year at Tuks. He shares his excitement: “This field fits perfectly with my additional interest in the medical field. I almost couldn’t believe it at the time. How cool is that! Coming full circle from my first year when I thought I had to choose between the two fields. I could now combine the two. It was a pretty awesome! I realised that I had the necessary skill and knowledge foundations, which I could implement to genuinely help people or animals with the work I am doing in a more direct fashion. Throughout my undergrad I couldn’t quite discern what my purpose or possible contribution to the engineering field might be. With this door being opened up, I finally found a place where I could genuinely make an impact. I decided to pursue my postgrad at Stellenbosch because of the evident drive, passion, support and backing the Biomedical Engineering Research Group (BERG) had to offer. It was evident from the first email interaction I had, that BERG was looking to make a genuine impact on the community and wanted to prepare and support their students accordingly.”

How did he choose the topic for his master’s? “Funnily enough, I didn’t end up choosing my topic so much, but it was more of a situation where the topic chose me. In the final year of my BEng (Mechanical) degree, I conducted my final-year research project on improving the biofidelity of a canine spine segment model. I had approached a few possible supervisors and expressed my interest in orthopaedic engineering, injury biomechanics and prosthetic design work, making them aware of my undergrad research work relating to canine spines as well. When my future supervisor (Dr Cobus Muller) was then approached by a vet (Dr Morné de Wet) looking to do some research in the design and implementation of a canine knee (stifle) implant solution, Dr Muller approached me and allowed me to interview for the topic. I was fortunate enough to get the topic and once again do some research in a field that genuinely interests me. Sometimes you’re just in the right place at the right time. Dr Johan van der Merwe eventually took over as my supervisor when Dr Muller left the Department after my first postgrad year. Both of them, along with Dr de Wet, had a massive part to play in the success of my research and I’m very thankful to them for all the help and supervision they provided me.”

Oscar explains what his work entailed: “Canines often incur injury in the knee joint, which can mostly be treated by conservative means. When the pain or injury in the knee joint does not resolve after making use of rehabilitation or pain relief methods one has to look to total knee replacement in order to make such pain subside. The pain experienced in these cases can be so severe that the canine loses full mobility in the knee joint. Unfortunately, more often than not, canines have to be euthanised in these cases, due to the cost and availability of this technology.

“I basically designed a total knee replacement for dogs (femoral and tibial components) by making exclusive use of open-source software (freely downloadable from the internet) throughout the design process of the implants. I also made use of open-source software to design the surgical equipment that was used throughout the mock surgical procedure. Initial tests and designs and surgical procedure verification were conducted on a 3D model of the stifle joint (knee of a dog), before moving on to cadaveric specimens, with the help of a qualified veterinarian. A knee test rig was used in an open-chain configuration, mimicking flexion and extension of the knee joint, in order to get data that could be compared pre- and post-implant. A tension force sensor was used to measure the quadriceps forces experienced throughout the induced flexion-extension motion. An NDI motion tracking system was utilised to track retroreflective markers placed on the femur and tibia of the specimen, from which data could be used to calculate kinematic motion such as flexion-extension, abduction-adduction, internal-external rotation, mediolateral shift, anterior-posterior drawer and joint compression-distraction.

“The main functional objective of the implant was to mimic kinematic mobility as close as possible to that of the healthy canine knee, especially for the flexion-extension range during knee motion. From the passive range of motion tests performed pre- and post-implant, a flexion-extension range of 95,6% and 87,2% was restored for the Labrador and German Shepherd specimens respectively, with post-implant flexion-extension results achieved in this research being similar, or in some cases better, to results seen in past studies. By implementing an entirely open-source design solution from start to finish, a major step towards accessibility and implementation of a product such as this has been taken.”

Regarding the contribution of his research, Oscar notes: “Overall, the joint kinematics of the open-source design approach, seen in my research, compared well to the motion profiles of a healthy knee, generating implant components for three different cases, with promising kinematic results. A design model was generated that has evident commercial potential for canine TKR (total knee replacement) implementation. This research has contributed to canine knee research by additionally showing translational movement in the knee as well, along with the angular kinematic data and quadriceps force data. The femoral and tibial implant design approach, based on healthy articulating knee joint geometry, in combination with the exclusive use of open-source software throughout the design process, amounts to a novel contribution to the field. In the end, I just hope that this research can make an impactful contribution and help improve the lives and jobs of our pets and vets.”

Oscar found his postgraduate studies challenging, rewarding and enriching. His experience, attitude and approach can provide valuable insight to any undergraduate student considering postgraduate studies: “Working on something that hasn’t been done yet and discovering new ways of doing things was a definite plus. I think that anyone who decides to pursue a research-based master’s has a drive to discover or create something new or innovative to a certain degree. At least for me, I know that I enjoy learning new things all the time, the pursuit of knowledge and intellectual challenge. In my eyes, success can be achieved with the perfect combination of cool, rational logic and innovative thinking.

“Most of the time spent during a master’s is repeatedly trying to solve a problem and repeatedly finding ways of how not to do something. This can be disheartening at times, and there were times when I wondered if there even was a solution, but you just keep on pushing, and when that lightbulb eventually goes on, it can be one of the most satisfying feelings ever. One of the biggest joys was when I finally solved a problem that I had spent ages on, in one case struggling to implement a certain concept into my calculations for more than two months. That feeling makes all the hard work well worth it.

“Seeing as a master’s is very much self-driven and relies heavily on the time, effort and work you put into it by the end of it, there’s this feeling that you can’t stop working, a constant stress and pressure that you put on yourself to keep on performing. Often there was a guilt-feeling in the back of my head that told me ‘you could be working right now’ whenever I took a break. It took me a while to get around that feeling and realise that it’s OK to take breaks, because this allowed me to have a mental reset and sometimes find a solution to a problem I was struggling for hours or even days on, just by distancing myself from it and getting new perspective to tackle it in a different way. So, don’t be too hard on yourself, your master’s might seem like the most important thing while you’re doing it, but there are more important things in life. Doing other things and finding the right work-play balance can give you renewed energy and new perspective. In my case, a healthy balance between the two resulted in me performing at a higher level in both aspects of my life, both complementing one other.

“Time management, with regards to setting yourself constant attainable goals to keep the research-train going, definitely played a big part. When I didn’t put in the work one week, I would have to pick up the slack the next. Once I learned to garner a better balance of constantly setting and achieving small goals, it became less of a challenge.

“Load shedding was an unexpected challenge I had to face during my master’s. I had a lot of 3D printed parts that I needed to manufacture that sometimes took more than 12 hours to print, but during a certain time period we had load shedding in constant intervals smaller than 12 hours. Now you might think that the department has generators, and this shouldn’t be a problem, however the small moment it took for the generators to kick in would stop the printer and then I had to start the printing from scratch again. It was easily solved though, by printing less at a time and knowing the Stellenbosch load shedding timetable off by heart, so that I could still get all the components I needed to print done in time. Thinking back on it, this small hiccough in the process makes me smile, it seems kind of funny in a way.

“Another challenge I had, which was very specific to my research, was having to deal with working with canine cadaveric specimens. Before I saw my first cadaver, I had to mentally prepare myself and it still hit me a bit hard. I guess it had to do with the fact that I grew up with close relationships with dogs and a love for all things living. Fortunately, I knew that the reason behind all of this was for a good cause and that my research would have a positive impact and help dogs in the future. I have to thank my girlfriend, Leonie Bell, in this regard. She is an excellent medical Doctor who could relate and help me prepare and recover mentally from working with cadaveric specimens. So, her support and encouragement was great and I’m extremely lucky to have had that kind of support.

Oscar is clear about his future plans. “I want to get into the Biomedical industry and get some hands-on experience in the field, because it’s all good and well to study and research in a controlled university environment (don’t get me wrong, this also comes with a whole lot of challenges), but I’m sure that there are quite different challenges in industry that I want to take on, learn of and overcome. The main driving force for my future plans is based on making a difference and impact on other people’s or animal’s lives, whichever shape or form that might take, be it starting my own Biomedical Engineering company or to become part of an existing company where I can have a genuine impact. In the words of Bigweld: “See a need. Fill a need.” – These words from the animation movie Robots have stuck with me since my childhood.

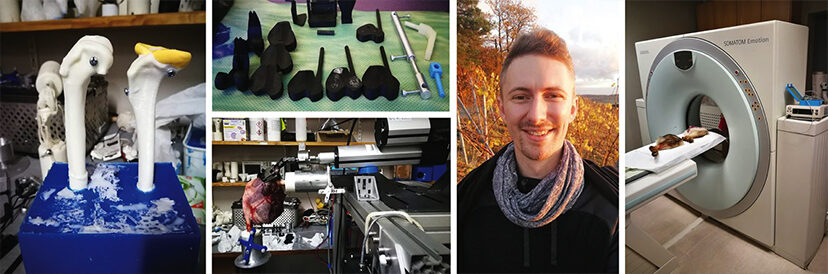

Photo collage:

Left: Canine bone models (femur and tibia).

2nd from the left top: Implant & surgical instrumentation prototypes.

2nd from the left bottom: Open-chain test rig configuration and motion tracking tool placements.

3rd from the left: Oscar Röhrs.

Far right: CT scan specimen positioning.