“Ruan was a supervisor’s dream: he was independent, a quick learner, and solved his own problems. Before long he also knew much more about the project details than me, so I could get out of his way and let him do the good work.” These are the words of Dr Neill Goosen, supervisor of Ruan Pretorius who received his master’s degree in Chemical Engineering cum laude in April 2020.

The title of his project was Design and modelling of an experimental tilapia and African catfish recirculating aquaculture system.

“My topic was very practical engineering in the sense that it was the design of a system,” says Ruan. “I liked that aspect of the topic and thought that it would be a good introduction to the world of engineering design. I have always been interested in science. I used to watch shows like Mythbusters and page through Popular Mechanics magazines when I was younger and it really inspired me to follow a career related to science and figuring things out.

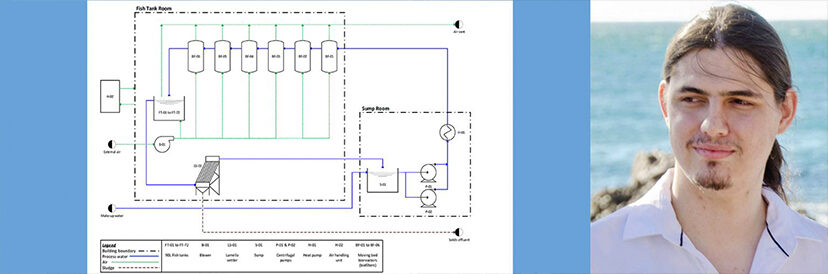

“My research topic in a nutshell was to design a water system that is capable of growing both African catfish and tilapia for research purposed at Welgevallen, one of the University’s aquaculture research laboratories. The type of system designed was a recirculating aquaculture system (RAS), which means that most of the water exiting the fish tanks is reused after flowing through a water treatment system. The water conditions in a RAS such as toxin levels, oxygen levels and temperature can be controlled, which is preferable for research trials where water conditions can easily affect the experimental results. I used literature data and models to predict the efficiency of the water treatment steps in the RAS (biofiltration, solids removal, aeration, temperature control) and estimated the total costs of constructing the system. We also tried to re-use as much of the current existing equipment and infrastructure that is currently unused at the Welgevallen facility and luckily, we were able to propose the re-use of the building, pumps and fish tanks.”

Ruan’s decision to opt for Chemical Engineering was inspired by his father’s field of study. “My dad studied process control and instrumentation engineering and was a big inspiration for going into the process engineering/chemical engineering field. It also appeared to me like the most interesting choice out of all the engineering fields.”

Ruan explains: “My research project will hopefully result in the system that I have proposed to actually be built. I believe that there is a real need for extra capacity and drive for aquaculture research as it is currently the fastest growing industry in the aquaculture sector. It would serve Stellenbosch University well to stay on top of the aquaculture research trends and I see my master’s research project as forming part of that effort.

“I decided to do postgrad as it opens a lot of job opportunities and I did not have any other jobs lined up. I also had the opportunity to do a master’s thanks to the financial support of my parents. Doing postgrad requires a large amount of self-discipline and driving yourself to work hard over months without immediately seeing results. That was definitely a challenge, but it also comes with a lot of freedom, which I loved. I was fortunate to get a part-time job as junior consulting engineer for a salmon farm feasibility study in September of my first year of postgrad studies, which definitely added to the challenge of finishing my thesis. The past two years were definitely the most challenging years of my life, but also the most rewarding. I was able to get married, afford my own accommodation and lifestyle and build up experience in the real life industry at the same time. I would recommend postgrad to anyone if they feel they have the will and resolve to undertake it.”

Ruan has a full professional and personal life. “Currently I am still working for the same company called Cape Nordic Corporation, which is finishing a bankable feasibility study for the construction of a 1 800 ton per annum salmon farm situated on the West Coast near Dwarskersbos. Additionally, I am forming a partnership with several colleagues to develop a company for seawater reverse osmosis desalination integrated with renewable energy. On the side I am also doing gigs as a drummer and keyboardist (pre/post-COVID 19 lockdown) as music is also one of my main passions.”

During lockdown, Ruan has been able to continue his work. He notes: “My engineering consulting has always been from home and therefore I am lucky to continue with business as usual. Additionally, I have spent my lockdown longing for an ice cold beer…”

He is clear about his future plans: “I plan to continue with the engineering work that I have been fortunate enough to get up until now. I also plan to travel abroad with my wife, taking on some overseas music gigs whilst working on engineering projects remotely.”

His supervisor, Dr Goosen, has the last word: “The fact that Ruan worked for a design company specialising in aquaculture system design is a testament to the quality of his work, dedication and his skills. Ruan is exactly the type of well-rounded professional that Stellenbosch is proud to produce, and I have no doubt that he will do well in future.”

Title: Design and modelling of an experimental tilapia and African catfish recirculating aquaculture system.

Summary: The project focused on designing an experimental recirculating aquaculture system (RAS) for the culturing of African catfish and tilapia. The RAS consisted of fish tanks, biofilters, solids removal by sedimentation, aeration by a regenerative blower and airstones and temperature regulation by a heat pump heat exchanger. Existing infrastructure such as the fish tanks, building and pumps were reused to reduce construction costs. The construction and purchase of equipment was estimated to cost R 145 000 and have an annual operating cost of R 79 000. The system was designed to produce fish at a density of 50 kg per m3.

Photograph: Ruan Pretorius and a technical drawing of his design that formed the main part of his research project.