[Article by Daniel Bugon]

The Department of Mechanical and Mechatronic Engineering’s research efforts to evaluate the impacts of digital twins and machine learning on the efficiency and safety of the SA Agulhas II and her operations are starting to bear fruit.

This is according to Prof Annie Bekker, who leads a research programme − the Sound and Vibration Research Group (SVRG) – at the Department of Mechanical and Mechatronic Engineering that investigates dynamic ship responses, shaft-line fatigue and structural fatigue on the SA Agulhas II.

Currently, the SAAII is studied by a research team consisting of: Brendon Nickerson (PhD student); Christof van Zijl (PhD student); Martinique Engelbrecht (MEng Research); Armand van Zuydam (MEng Research); Ben Steyn (MEng Research); Nicole Taylor (MEng Research); Jesslyn Bossau (MEng Research); Nic Bunn (MEng Research); Gerhard Durandt (MEng Research); Jaco Laas (MEng Research) and Karl Pferdekamper (MEng Research).

COVID-19 exposures played havoc with the ship’s itinerary, delaying its departure to Christmas Eve and resulting in a later return in the colder circumstances of the late Austral summer.

December 2020 marked the eighth year of the SVRG performing full-scale measurements on the SA Agulhas II during her annual relief voyage to Antarctica.

During the voyage, the SVRG installed an additional 500 metres of cable on board the vessel to include measurements of the oil temperatures of the propulsion bearings and vibration on one propulsion motor.

These measures were introduced to fulfil Stellenbosch University’s commitment to a two million euro European Union MarTERA project, called HealthProp. This project aims to contribute a digital twin model for the propulsion system in ice with partners in Norway and Germany.

Four students worked with the crew to perform this installation by feeding sensor wires through the narrow void spaces of the ship’s double hull. They were required to quarantine for seven days before being allowed to go on board and had to live on the ship without disembarking during the week-long instrumentation effort (click here to watch a short, 3-minute YouTube video).

The effort immediately paid off when the ship encountered a severe storm on New Year’s Day.

“The ice-going hull is rounded and has an extended stern. This disposes the ship to bow and stern slamming. Stern slamming is especially problematic as it causes whipping, or jelly-like bending of the vessel which lasts for up to 40 seconds. This jelly-like bending is not accounted for in the current state-of-the-art hull design fatigue life designs. The same three-metre wave that impacts the stationary vessel from the bow would cause it to bend 10 times more if it impacted it from the stern. Our new instrumentation efforts, which include mid-ship strain gauges, enabled us to quantify the contribution of this effect,” said Bekker.

On her departure, the SA Agulhas II encountered challenging ice conditions which required the ship to ram her way through the sea ice. This turned out to be great news for SVRG’s research efforts as they were able to gather an increasing cohort of data on ice impacts and the vibration responses of the 30 metre long propulsion shaft.

Furthermore, they were also able to conclude that the SA Agulhas II operated conservatively in ice, but regularly utilised the extra propulsion power (1 MW per motor) intended for ice navigation to gain two knots of additional speed to reach destinations more quickly in open water. This mode of operation almost doubles the amount of fuel burnt.

As a result of these valuable operational insights, the SVRG is now able to prototype power projections for a proposed route based on the weather and desired speed using physics-based models in computational fluid dynamics and machine learning algorithms based on neural networks.

“We have also developed a human digital twin which can reflect the location and state of motion sickness of crew and scientists on board,” said Bekker.

She added that through extensive surveys of human responses to wave slamming they are in a position to contribute a vibration dose threshold for comfort which could influence ship design in the cruise industry.

“In my mind the ship of the future will have a digital counterpart which will be accessible to its stakeholders,” she said. “Sensors, models and physical assets will merge into a combined asset – and business will be driven by novel services which can be delivered through the innovative and reliable combination of these.”

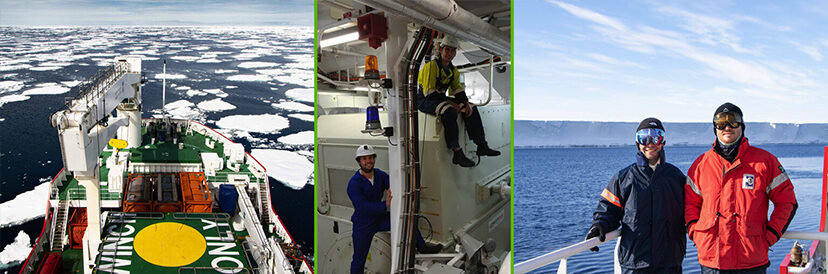

Photographs: (Left to Right)

1. The SA Agulhas II entering the sea ice during the 2020/21 SANAE Relief Voyage.

2. Nicholas Bunn and Ben Steyn installing new cables and sensors on the 4.5 MW port side propulsion motor.

3. Nicholas Bunn and Karl Pferdekamper smiling as they arrive at the Fimbul Ice Shelf, Antartica, after a 12-day journey through the Southern Ocean.

Photo credit: Karl Pferdekamper